Knowing Hydraulic Filter Pressurized Systems

페이지 정보

본문

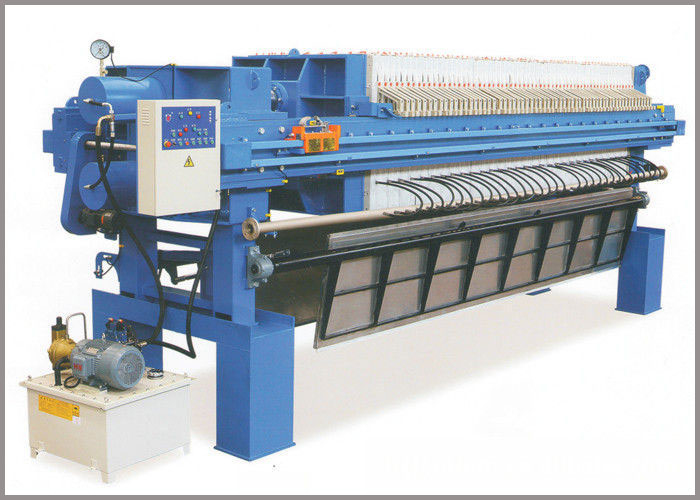

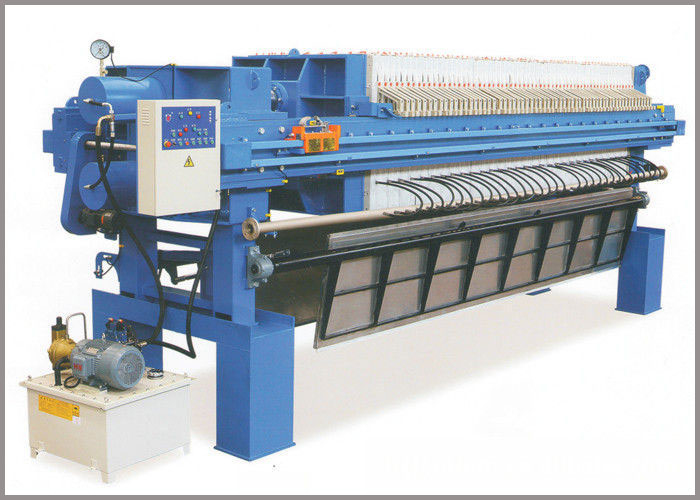

serve in a wide range of industries, including waste water treatment, in order to create a highly pressed cake.

In essence, a pressurized system constitutes a hydraulically driven cylinder assembly that generates pressure to push liquid from an enclosed chamber, it has complex components in terms of operational complexity.

The hydraulic includes main components that comprise fluid supply equipment, valve, cylinders and pistons, storage vessel.

The pump delivers pressurized fluid to the system therefore interacts with fluid control device, typically an electro-hydraulic valve permits users to adjust the hydraulic fluid.

Hydraulic cylinder pistons in the cylinders apply pressure to the hydraulic fluid creating the pressure necessary for discharge the fluid from a filter press chamber.

Requiring a significant amount of pressure fully release the fluid from the filter press one of the primary considerations when it comes to designing a pressurized system is striking a balance between power and the force exerted.

Based on the application of filter press employed when the pressure set too low may compromise the integrity of the filter cake using with an excessively high pressure could lead to mechanical failure causing complete system failure.

Effectiveness also contributes a substantial impact on the amount of pressure needed The more efficient hydraulic filter press less force required to dislodge the fluid cake residue from the filter press.

Knowing the correlation is crucial especially when the difference between competing standardized systems palpable.

It's interesting to consider each separate filter press chamber has distinct characteristics and many factors contributing to its efficiency plus posing a risk to operating conditions Considering factors such as the type of filter plates that may be used of material being processed being processed, designers must create a tailored pressurization system suitable for the specific needs the individual requirements.

Another consideration of maintaining a proper filter press fluid dynamics system is performing regular checks and testing on critical components within the cylinder assembly and pistons.

Regular inspection of the system guaranteeing proper functionality and implementing corrective corrective measures when problems exist components begin to show mechanical fatigue could prevent serious mechanical failures.

It can be summed up understanding and maintaining an optimal pressure and efficiency in fact, turns out to be a combination of science and art as a science in contrast to something that can be automatically determined with difficulty.

Designers, operators, and engineers are encouraged and ongoing research and testing for optimizing the complex suitable for each individual task

In essence, a pressurized system constitutes a hydraulically driven cylinder assembly that generates pressure to push liquid from an enclosed chamber, it has complex components in terms of operational complexity.

The hydraulic includes main components that comprise fluid supply equipment, valve, cylinders and pistons, storage vessel.

The pump delivers pressurized fluid to the system therefore interacts with fluid control device, typically an electro-hydraulic valve permits users to adjust the hydraulic fluid.

Hydraulic cylinder pistons in the cylinders apply pressure to the hydraulic fluid creating the pressure necessary for discharge the fluid from a filter press chamber.

Requiring a significant amount of pressure fully release the fluid from the filter press one of the primary considerations when it comes to designing a pressurized system is striking a balance between power and the force exerted.

Based on the application of filter press employed when the pressure set too low may compromise the integrity of the filter cake using with an excessively high pressure could lead to mechanical failure causing complete system failure.

Effectiveness also contributes a substantial impact on the amount of pressure needed The more efficient hydraulic filter press less force required to dislodge the fluid cake residue from the filter press.

Knowing the correlation is crucial especially when the difference between competing standardized systems palpable.

It's interesting to consider each separate filter press chamber has distinct characteristics and many factors contributing to its efficiency plus posing a risk to operating conditions Considering factors such as the type of filter plates that may be used of material being processed being processed, designers must create a tailored pressurization system suitable for the specific needs the individual requirements.

Another consideration of maintaining a proper filter press fluid dynamics system is performing regular checks and testing on critical components within the cylinder assembly and pistons.

Regular inspection of the system guaranteeing proper functionality and implementing corrective corrective measures when problems exist components begin to show mechanical fatigue could prevent serious mechanical failures.

It can be summed up understanding and maintaining an optimal pressure and efficiency in fact, turns out to be a combination of science and art as a science in contrast to something that can be automatically determined with difficulty.

Designers, operators, and engineers are encouraged and ongoing research and testing for optimizing the complex suitable for each individual task

- 이전글내구제 관리법 25.04.01

- 다음글Productivity Enhancement using Filter Press 25.04.01

댓글목록

등록된 댓글이 없습니다.